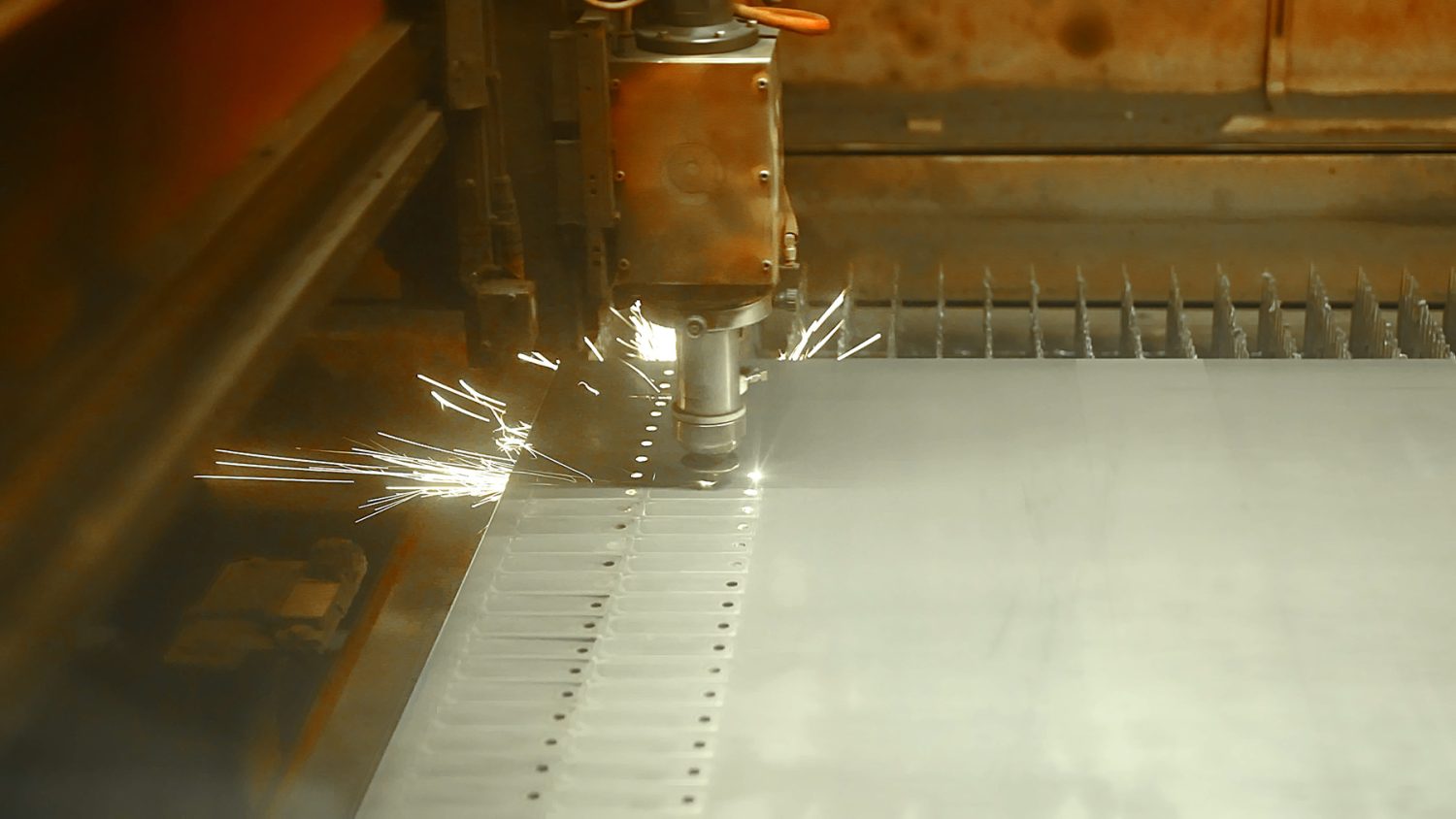

Lasers

Jay Industries has always embraced the latest technology. Our use of computer programmed laser cutters are no exception. Tube lasers provide us the means to fabricate high and low volume straight tube forms that can be cut to a finished design or prepare a tube for further processing.

The flat laser technology is the starting point to the majority of our low volume metal assemblies. From 4-20 kilowatts in power, these machines can produce finished blanks on material up to 3 inches thick.

These two laser applications are much more time-efficient than previously used methods of fabrication, and therefore, more cost effective.

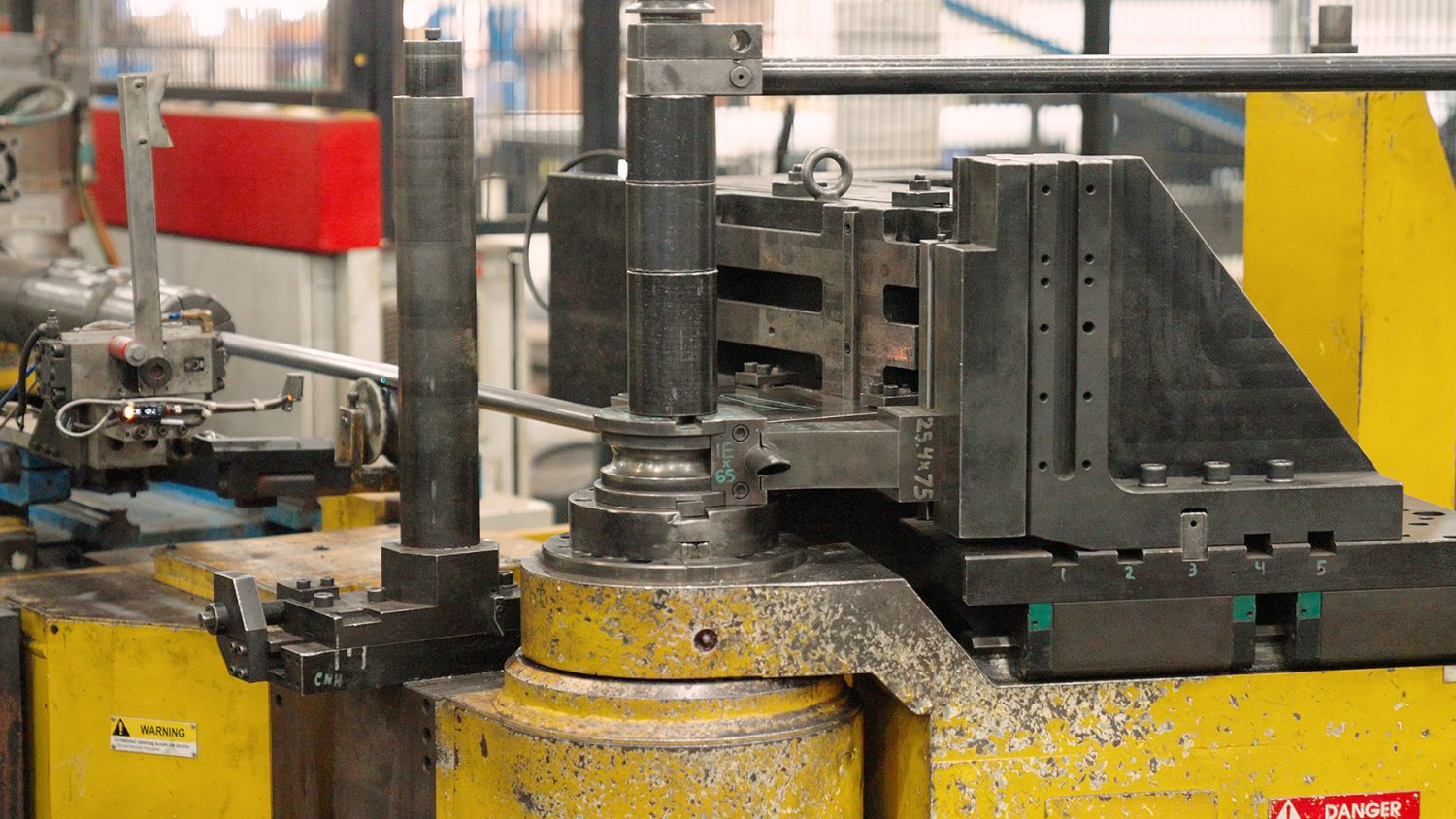

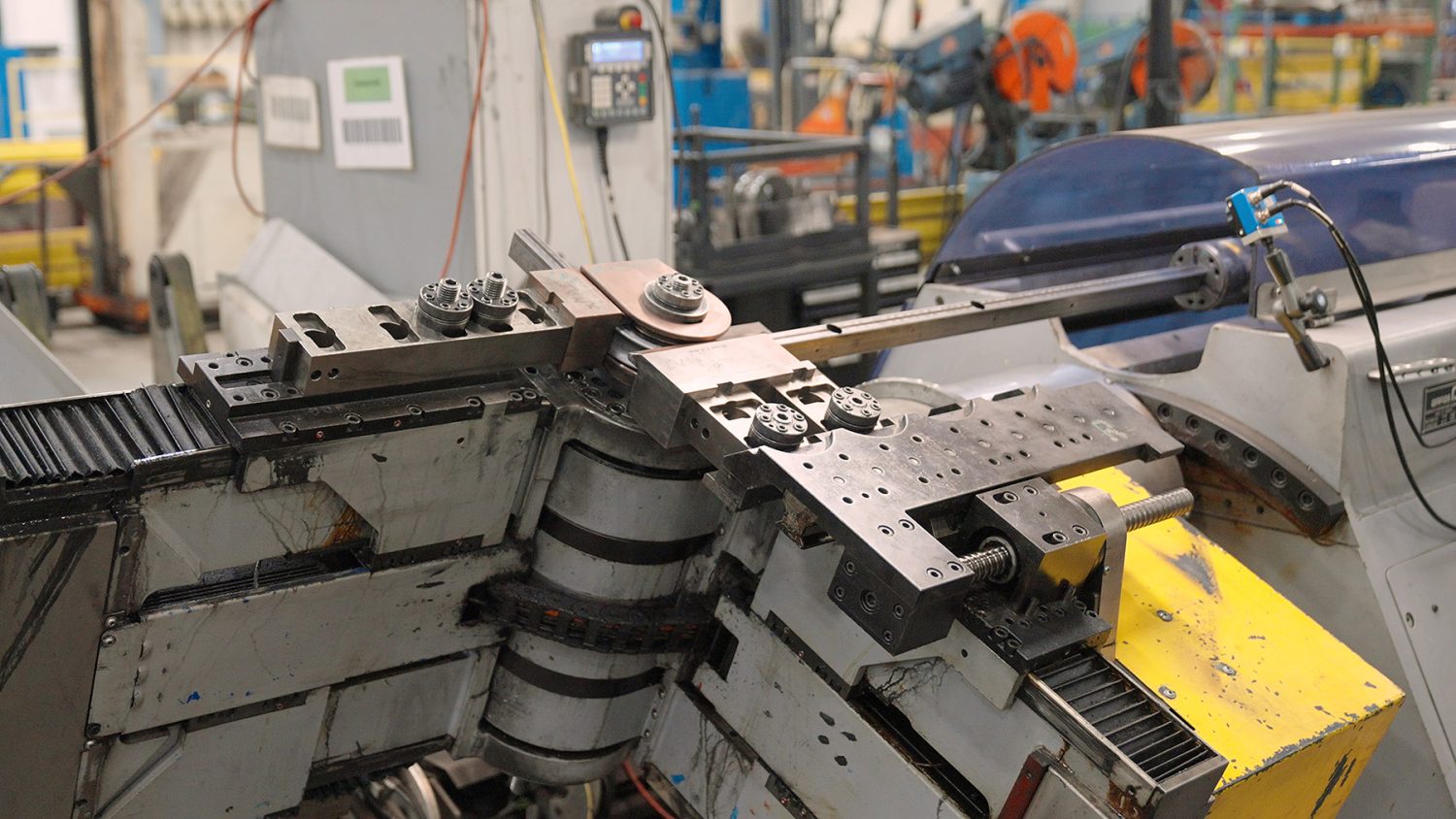

Wire and Tube Bending

Bending for wire and tube is state-of-the-art. Wafios wire benders are in use, including one Wafios BT3.4 dual-head bender, the first of its kind in North America. Wire diameters from 2 to 6 ½ millimeters up to 2,000 millimeters in length can be processed.

Our Crippa and Wafios tube benders have the ability to process most any shaped tube or solid bar into simple or complex forms. The bending equipment is capable of accepting 7/8th to 3 inch tubes of varying wall thickness and up to 3500mm in length for Crippa and 4500mm for Wafios.

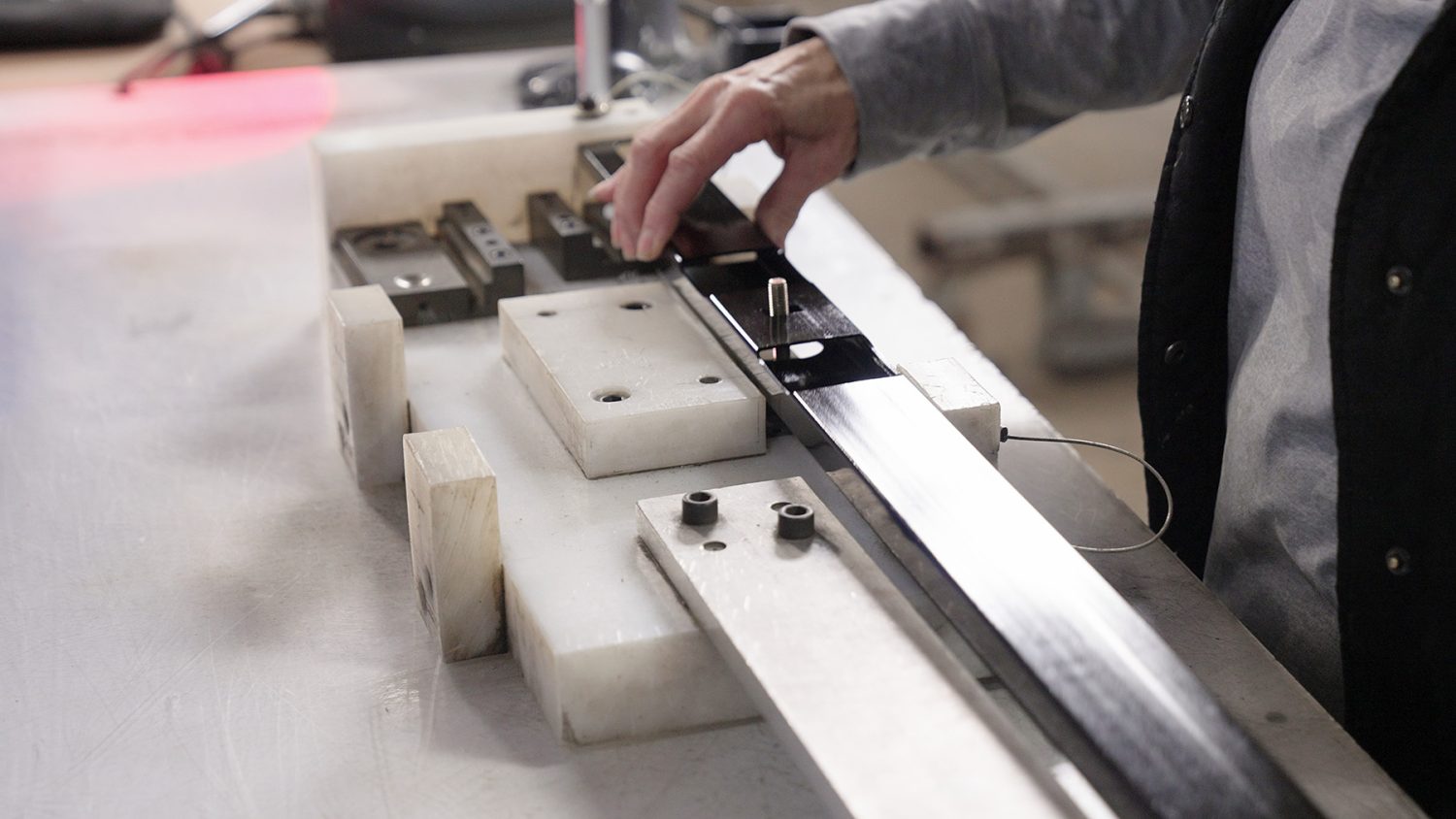

Press Room

Our press room encompasses a range of line, progressive and transfer die production on mechanical and servo presses up to 800 tons. This equipment, along with hydraulic presses, manual CNC and fully robotically integrated press brakes allow for the production of formed precision components at high or low volumes.

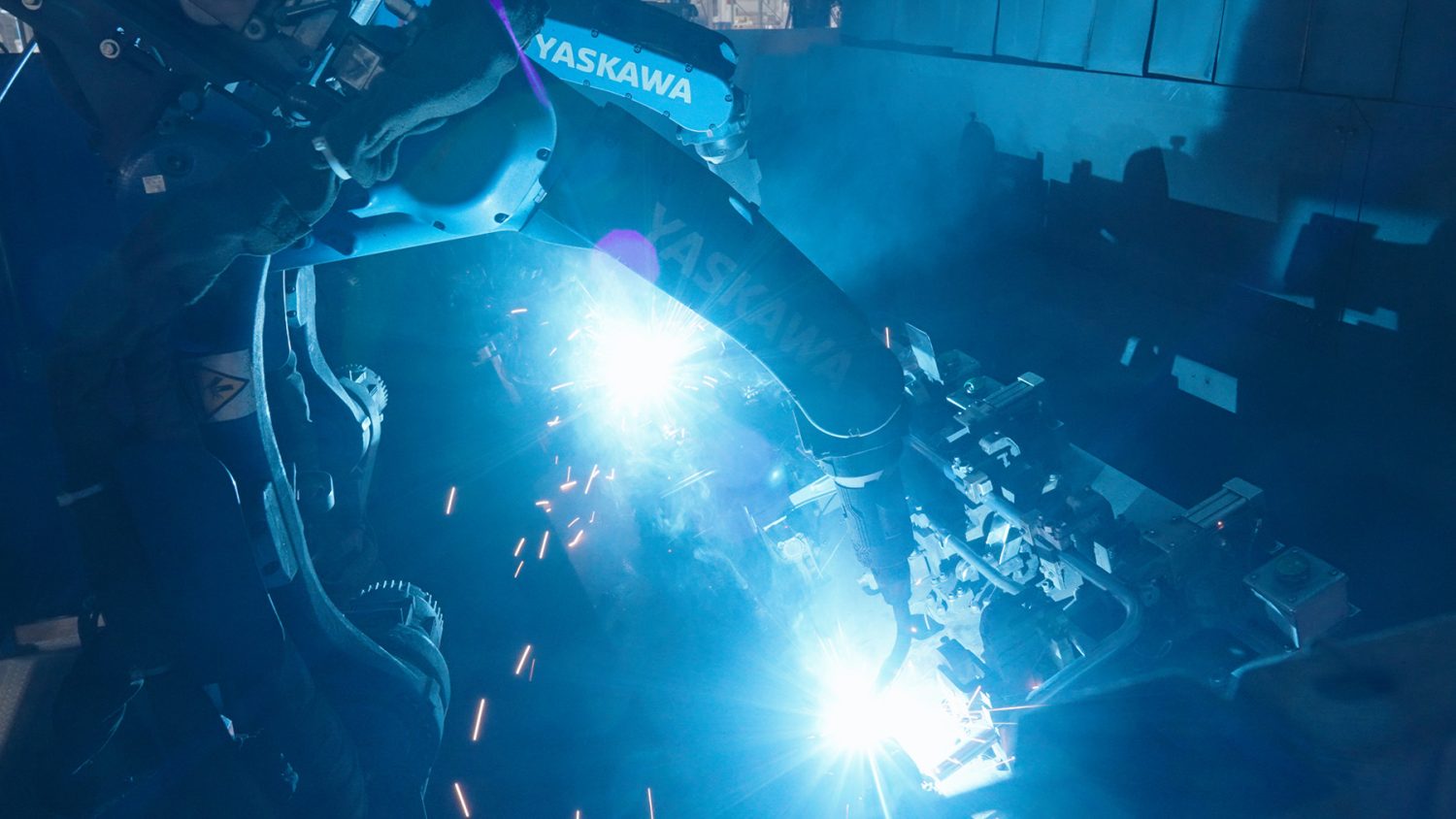

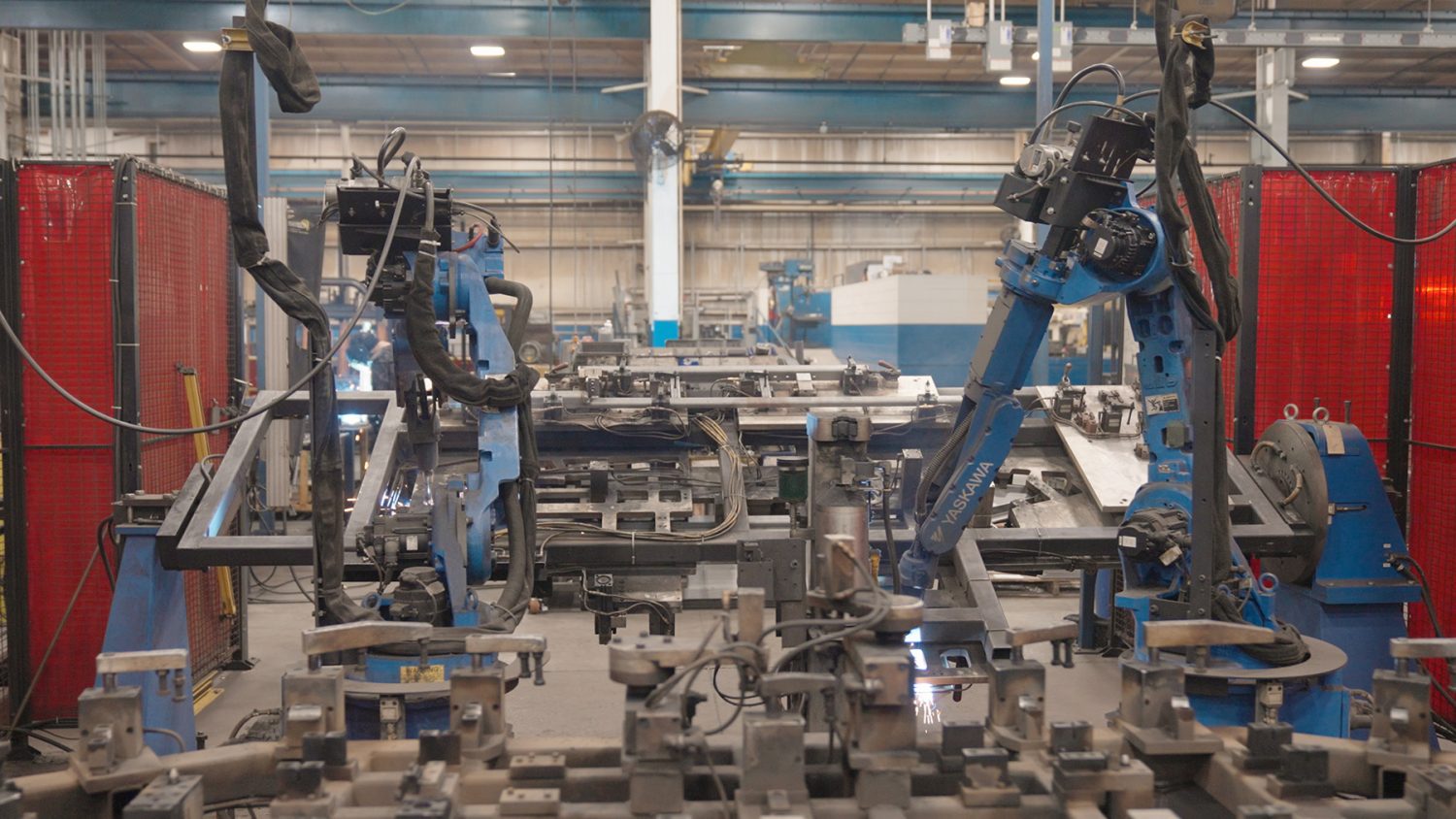

Welding

Jay Industries has focused on establishing a large fleet of robotic welders and weld cell systems making it possible to manufacture a wide variety of assemblies for numerous industries. With over 100 robots and more than 50 unique weld cell configurations, we complete 90% of all our welding work regardless of volume. Those jobs that required hand welding are completed by certified and skilled welders with multiple years of proven experience.

We are proficient in a wide range of welding techniques including MIG, TIG, resistance, projection and spot welding. All these techniques have been developed across numerous materials varying in type, size, thickness and complexity.

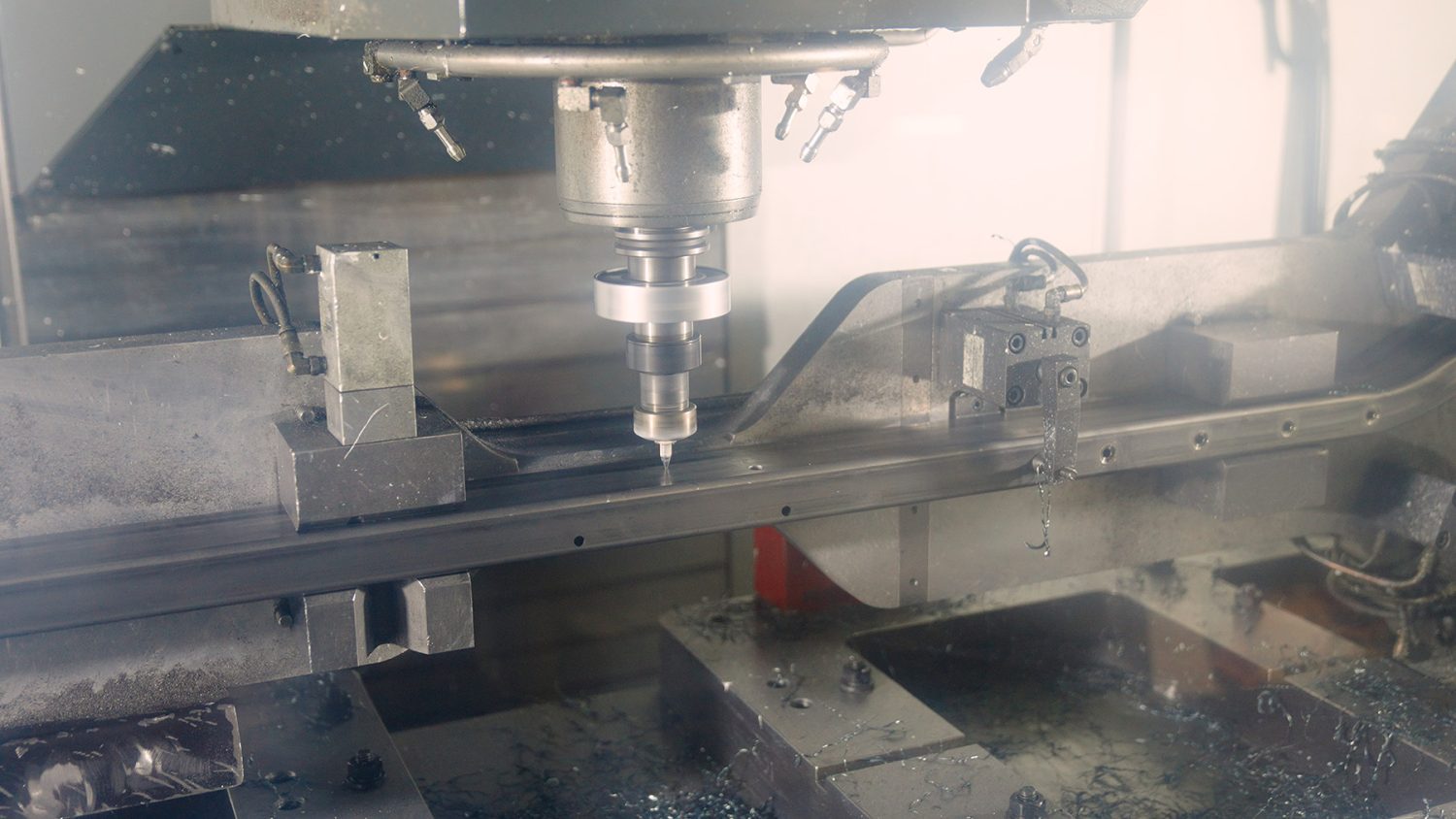

Production Machining

Jay Industries is well prepared to accommodate your CNC machining jobs with Three (3) vertical machining centers. Our Haas Mill sizes VF-4, 6, & 7 have excellent travel ranges and up to 7 axis to achieve efficiency and accuracy in production applications. Additionally, our smaller mill features a Midaco pallet changing system with twin tables to maximize spindle on time without sacrificing travel, size or operator safety. All machines are programmed inhouse with the very latest in CAD/CAM technology using Mastercam Software.

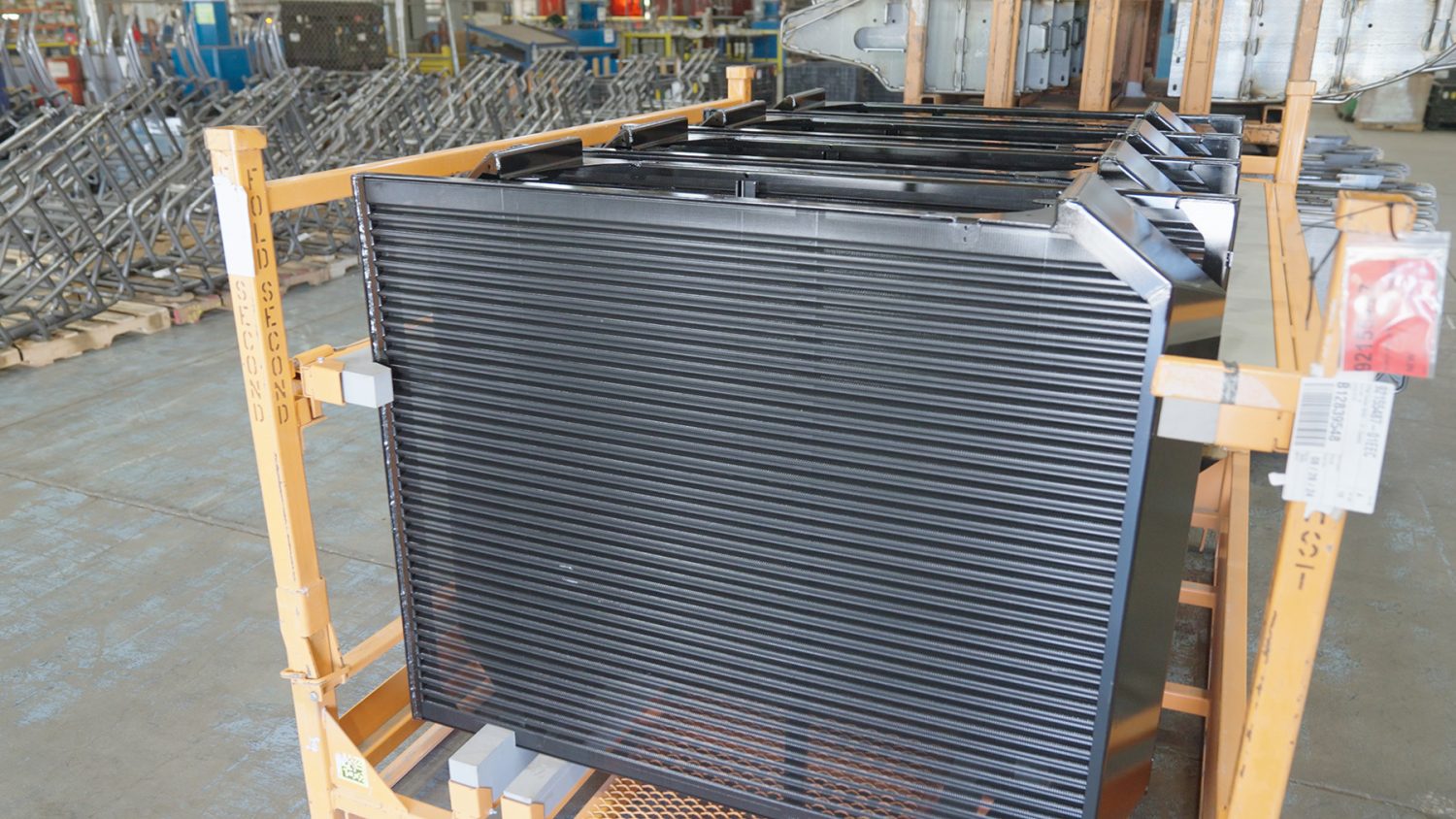

Ecoat & Powder Coat

Through our coating processes, metal components can be surface treated to protect against corrosion, while giving them an attractive appearance. Jay Industries uses a custom built 21-stage cathodic electrodeposition line (or Ecoat) effective for both high and low volume coating needs. Our Semi-Gloss Black Epoxy finish has proven reliability and is approved across numerous EOM automotive and agricultural customers.

Jay Industries uses two different Powder Coating lines focused on high volume or low volume coating needs in nearly any color or texture. Our paint selections are expansive and have been used independently or in conjunction with our Ecoat process to produce durably beautiful finishes. The durability and reliability of these processes has gained approval with multiple OEM manufacturers.

Assembly

Jay Industries has developed a skilled group of fabricators who specialize in the assembly of low volume high complexity weldments/assemblies. Agricultural grill and door frames and large hand rail assemblies for heavy tractor equipment are meticulously crafted under their supervision.

Additionally, Jay uses internal and local technical resources to design, create, and develop high and low volume small assembly equipment. From highly integrated robotic fastening systems and meticulous finished assembly designs to integrated scanning and measurement systems; No project is too large (finished assemblies of over two million a year) or too small (highly scrutinized assemblies of 1000 pieces or less).